Quality Control Management Module

Good quality control of raw materials, goods, finished products... will prevent the production of poor quality products. BRAVO software helps businesses save time and effort in Quality Management (QC) analysis, goods circulation support operations and helps improve business reputation.

Overview of Quality Control Management Modules

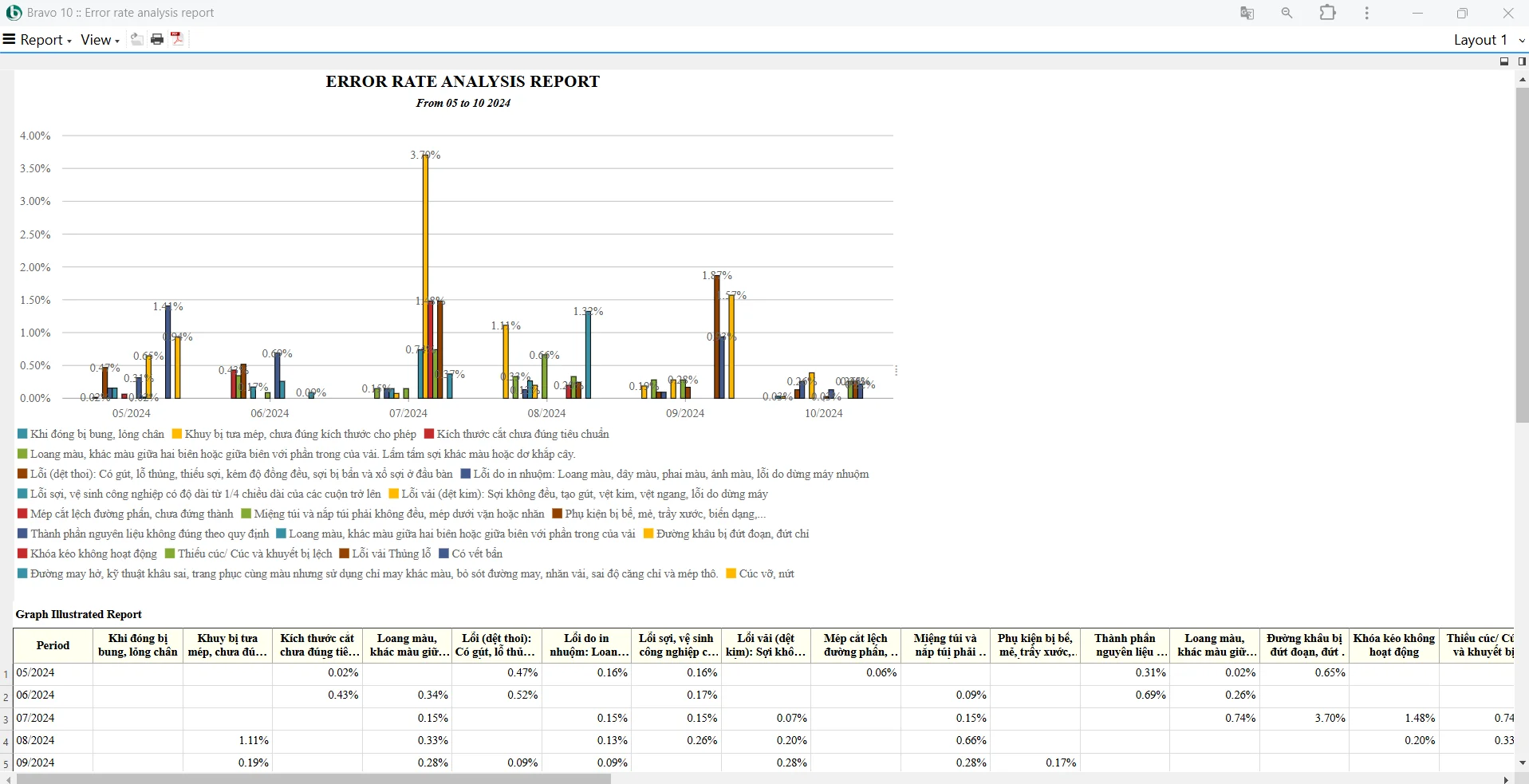

Assist in the work of controlling the quality of input goods, product quality in production and checking the quality of output goods... through statistics and assessment of damage and cancellation rates, error cause rates to have plans to handle, overcome and limit error situations. Support businesses to effectively control the quality of input materials and the quality of goods delivered to customers.

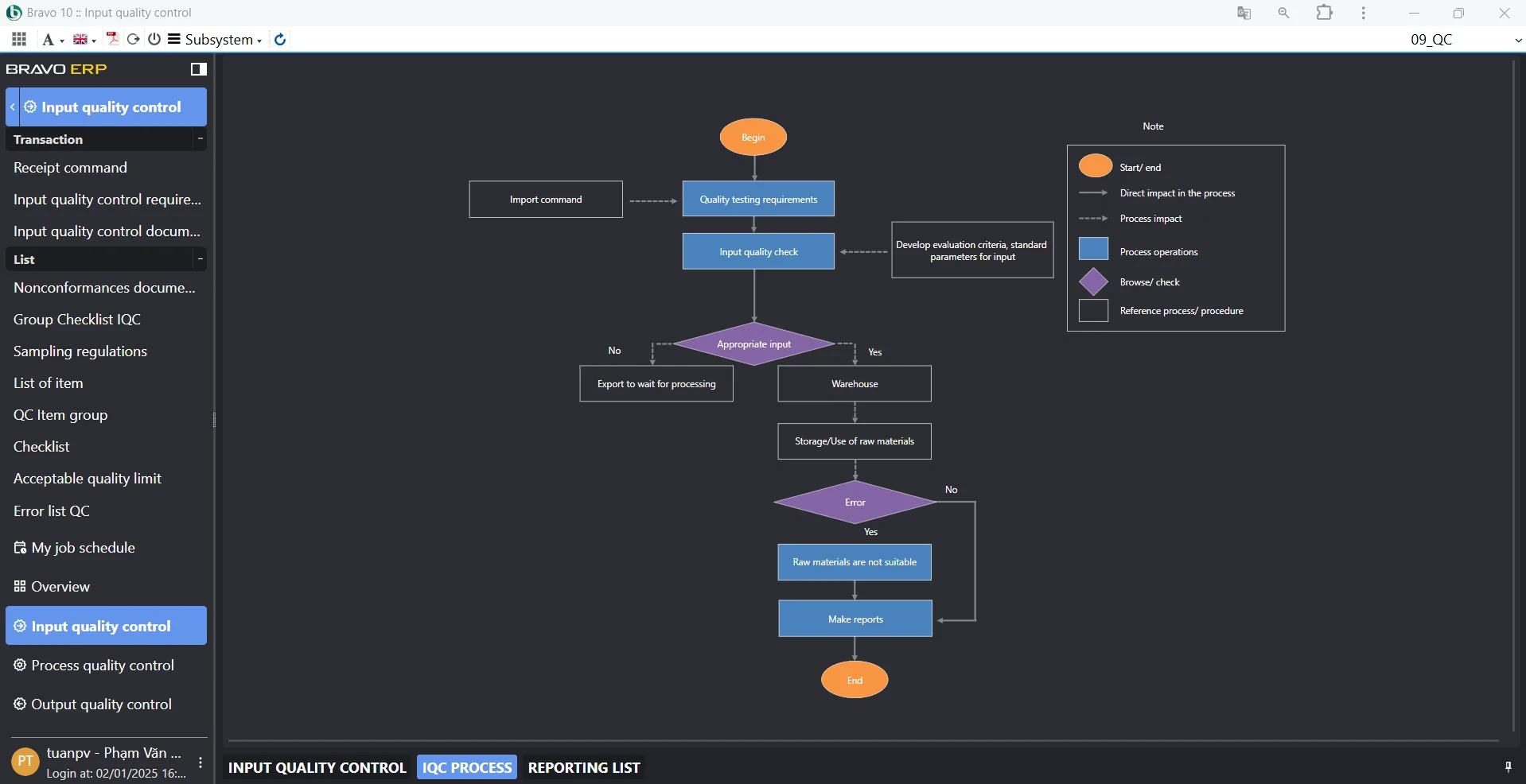

INPUT QUALITY CONTROL (IQC)

- Define Evaluation Criteria and Standard Parameters for Raw Materials/Finished Products.

- Control the Quality of Incoming Materials: Track and record actual data on quality control check sheets.

- Manage Non-Conforming Materials/Products: Monitor and handle non-compliant materials/products, assist with logging and identifying defects, and define corrective actions.

Input quality management interface (IQC)

PROCESSING QUALITY CONTROL (PQC)

- Declare evaluation criteria and standards for products at each production stage.

- Record product quality inspection results on the quality inspection form.

- Prepare reports to document solutions for handling non-conforming products according to regulations.

Production quality management (PQC) interface

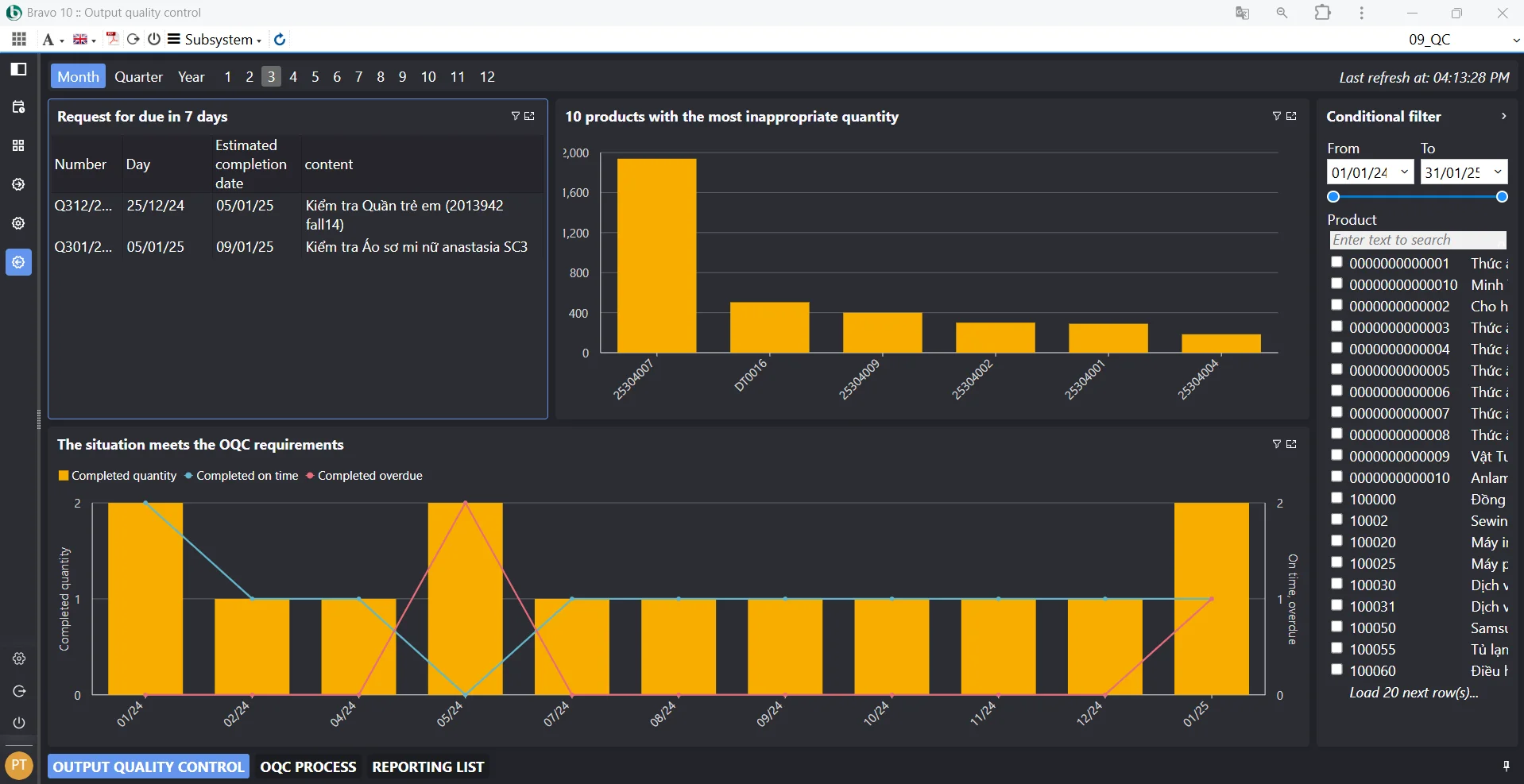

OUTPUT QUALITY CONTROL (OQC)

- Establish evaluation criteria and standard parameters for products to be sold.

- Record inspection results on the quality control output form.

- Prepare records for the destruction or disposal of products and goods that fail to meet requirements.

- Compile statistics on defective products to identify causes and develop corrective