Steel pipe manufacturing units

Software overview

Software BRAVO 8R3 When applied at units specializing in PRODUCTION, STEEL PIPE PRODUCTION is customized according to the characteristics of enterprises in the industry. The system is built with the purpose of helping businesses solve problems of administration and operation of processes built on the software under the mechanism of “coordinating – sharing – jointly controlling” control – accomplish together” between departments and divisions in the enterprise in order to improve and maximize production and business efficiency.

Problem of reading steel pipe production and processing industry

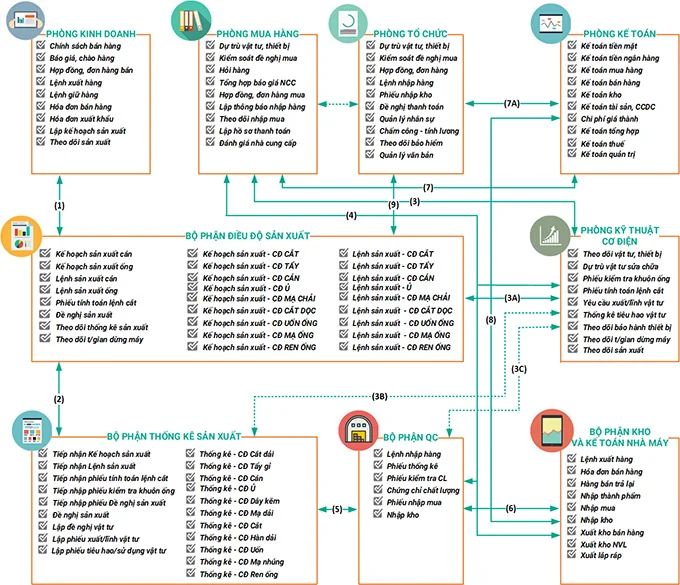

Units specializing in the production and processing of STEEL PIPEES in general and STEEL PIPE rolling and rolling production units in particular will build closed processes, improving their ability to coordinate, control and distribute resources one-on-one. optimal, fast and efficient way. Accordingly, the application process will be operated as follows:

1. Data organization system

2. Describe the main activities

- It is the starting point of the production process

- In addition to sales, the sales department bases on sales data to make “production plans” corresponding to reality, then moves to the factory to complete.

- When the production process is done, the sales department needs to monitor the production situation and capture the output, available inventory (soldable inventory) to coordinate the orders/contracts to develop. born.

Main tasks in the process

- Sales management: Revenue planning, sales policy making (price list, discount,…), making quotation, making sales orders/contracts/export contracts, making export orders/hold orders goods, making sales/export invoices, making delivery notes and shipping tracking, making sales returns.

- Planning and tracking production progress: planning “production output”, tracking detailed production plans/work orders, tracking production progress and production statistics, tracking inventory available stock.

- With the participation of all departments at the factory (factory board of directors and affiliated departments and divisions)

- Inheriting the “production plan” from the sales department and building detailed “production plans” according to the production stages

- Steel Rolling Factory, including stages: Strip Cutting Stage; Rust Removal Stage; Rolling Stage; Annealing Stage

- Steel Pipe Factory, including stages: Zinc Wire Stage; Strip Plating Stage; Cutting Stage; Strip welding stage; Bending Stage; Dip Plating Stage; Pipe Threading Stage

- Based on the production plan, the inventory of available materials will proceed to estimate materials for production

- Check and monitor machine downtime to estimate repair and maintenance materials

- Make purchase requests for materials, request for delivery/receipt of materials, transfer to technical department for inspection and send to purchasing department

- Based on the appropriate plan and resources, proceed to make “work orders” to transfer to the workshops and production stages in the factory to carry out the production process.

- Monitor progress, detailed production statistics according to production plans

- Coordinate, check and evaluate the quality of finished products

Main tasks in the process

Production Dispatching Department

- Receive and complete the Production Plan

- Detailed production planning step by step

- Make detailed production orders by stage

- Estimate and prepare material supply request

- Track production statistics

- Monitor machine downtime

Production Statistics Department

- Receive production plan/work order

- Production statistics by each stage

- Management of consumables

- Statistics of machine downtime

Quality management department

- Control and evaluate the quality of purchased materials (according to groups requesting to purchase materials)

- Measurement and quality control of finished products (mechanical, physical, chemical)

- Management of weighing stations for raw materials and finished products

- Monitor production progress

Electromechanical Engineering Department

- Manage the list of machinery and equipment, production lines

- Management of maintenance and repair of machinery and equipment

- Material management and planning

- Summarize the request for supply of materials (repair and maintenance supplies)

- Summary of proposals to buy materials

- Control and evaluate the quality of purchased materials (according to groups requesting supplies)

- Pipe mold control

- Make a cut order calculation sheet

- Monitor downtime

- Monitor production progress

Warehouse department and factory accounting

- Receipt of import notices

- Receipt of export/keep orders

- Warehouse management: purchasing, warehousing, importing finished products

- Warehouse management: export sales, export raw materials, export assembly, export transfer

- Update accounting data arising at the factory

- Play the role of coordinating materials to serve the production and business process

- Based on actual inventory and production plan to estimate materials

- Based on actual arising, the materials department inherits, controls and processes the “request for supplies” groups from the updated departments.

- After completing the “request for materials”, conduct inquiries, collect quotes and evaluate, select the most suitable supplier.

- After the leader approves the supplier, prepares orders and contracts (according to quotes) and monitors the purchasing process.

- When receiving delivery notices from suppliers, proceed to make “notices/import orders” to relevant departments such as: Technical department, Quality management department, warehouse, etc. to arrange personnel. inspect, evaluate goods, raw materials and conduct purchasing.

- Simultaneously, proceed to make payment records for suppliers and transfer them to accountants for payment.

- After the process of purchasing and importing goods is successful, conduct a survey and evaluate the quality of each supplier as a basis for selection and purchase in the next time.

Main tasks in the process

- Budgeting for materials

- Purchase offer control

- Gather supplier quotes and reviews

- Manage contracts/purchase orders

- Make orders/notices to import goods

- Monitor purchase status

- Make a purchase payment record

- Supplier survey and evaluation

- Is the part that inherits all the data generated in the system

- Play the role of controlling financial activities corresponding to each business operation.

Main tasks in the process

- Cash accounting

- Bank accountancy

- Sales and Accounts Receivable Accounting

- Accounting for purchases and accounts payable

- Inventory managerment inventory

- Property Accounting and CCDC

- Cost accounting (calculating cost by stage)

- Tax accounting

- Management accounting ( general accounting data for the whole system: offices, factories, branches)

- Manage purchasing process (supplies, office equipment) independent of supplies department

- Administrative management (documents, distribution of work uniforms)

- HRM

- Timekeeping and statistics

- Payroll

- Insurance tracking

Solution of BRAVO

1. Software database organization

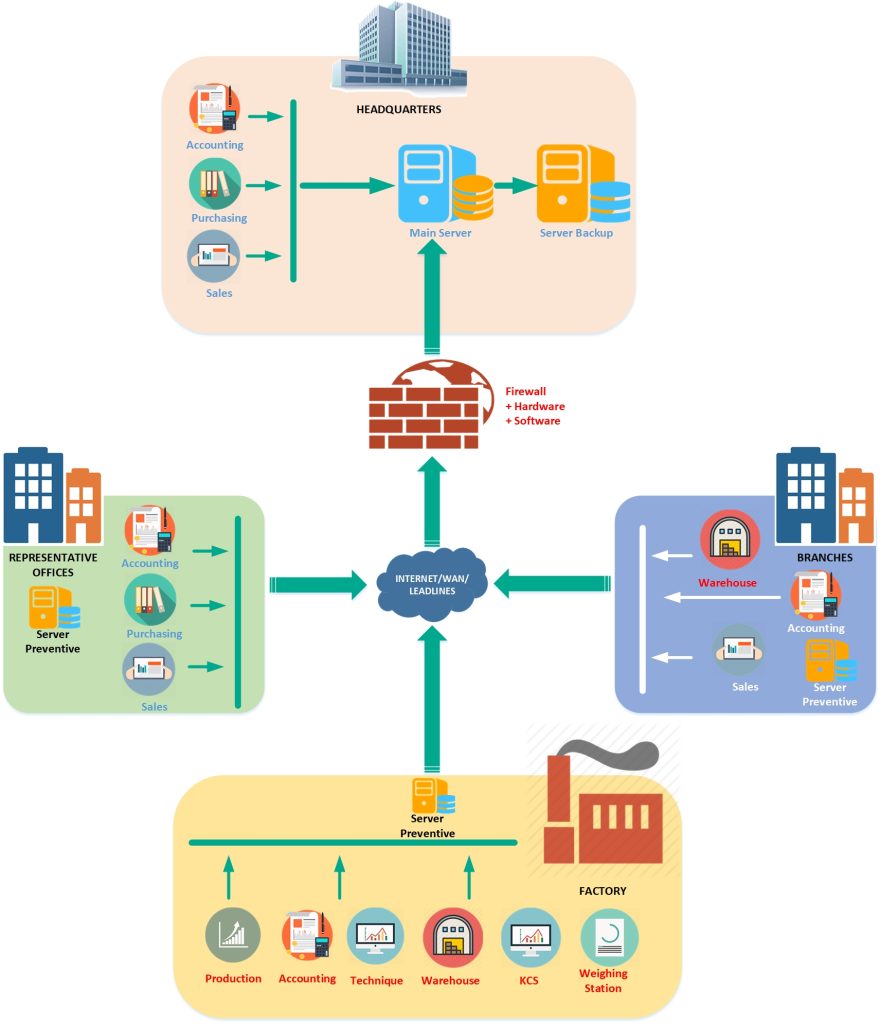

The common characteristic of manufacturing enterprises is that the production and business areas are dispersed in many different locations and areas (offices, factories, sales warehouses, branches, …). Therefore, in addition to the needs of customers, when building solutions, BRAVO consults on solutions to organize and stream data for convenience in business operations, closely in management of development issues. Generate and synthesize all activities in the customer’s production and business organization system.

a.Organizational model for updating and exploiting system data

As mentioned, because the locations where the software is used are spread across geographical regions, BRAVO needs to build a data system that combines a synchronous and distributed data solution to ensure the timeliness of data.

Data (for problems of inheritance, tracking and management of data that arise) and continuity of data (to ensure continuous sales and production when there is a connection problem, reducing reliability). delay in deliveries that need to be continuously calculated such as sales, goods import, …)

- Data model

Data connection model

Describe

At the headquarters

- Install 01 BRAVO 7R2 software including “running program” and “database” on the server.

- At the departments, computers that are allowed to access the software (the Client) will be declared (machine name, user ID) and installed “running programs” for users to update information and data on the computer. software.

- The Users will be managed and decentralized in detail according to each user’s role in the relevant departments. Each part

At the factory and branches

- Installing BRAVO 7R2 software only includes “running program” (not including “database”) on client computers of departments, participating users use the software to update and transmit data online. about the software on the server at the head office.

- Users are decentralized and authorized to ensure independence and responsibility when updating data into the system.

(Recommendation: to ensure stability and data safety when operating the software, BRAVO recommends equipping a backup server, a backup server serving two main tasks: replacing the main operating server. On the main server and backup server integrate equivalent physical hard drives and configure according to hard drive Raid solutions: Raid 0, Raid1, Raid 10)

b. Grouping user data classes at each use location

In addition to inheriting data arising in the system, each department has its own, independent and sometimes confidential operations with other departments. Therefore, for users’ convenience in operating and manipulating the software, BRAVO divides the user interface into layers (Layout). Specifically:

At Headquarters: + Layout of the Board of Directors of the company + Sales Department Layout + Purchasing Room Layout – Import – Export + Layout of Accounting Department + Organization Room Layout | At the factory: + Factory Board of Directors Layout + Layout Department Dispatching Production + Layout Department of Production Statistics + Layout Mechanical Engineering Department + Warehouse Department Layout + Quality Control Department Layout + Factory Accounting Department Layout | At the branch: + Branch Board of Directors Layout + Sales Room Layout + Shopping Room Layout + Warehouse Layout + Layout of Accounting Department +Organization Room Layout |

Data screen at each use part

c. Organize and disassemble software database

In order for businesses to easily monitor, manage and aggregate data arising at each software operation location, BRAVO advises on data organization plans suitable to each size of the business. Accordingly, the software’s database (database) will be divided into data trays (called unit trays).

Facility corresponding to each point used to receive, store and process data arising at each point. And there is a general data tray that plays the role of aggregating/unifying data generated throughout the system.

Database organization model

Select base unit tray when using software

2. Handling specific operations of production and business

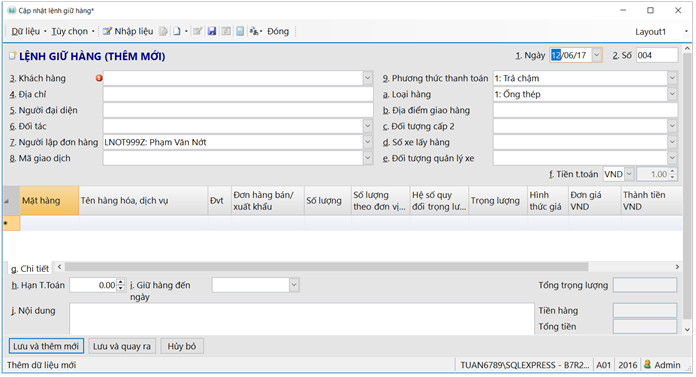

Set sales revenge

- Sales and export activities are conducted at the office (headquarters, branches) and the export and delivery are carried out at the factory. Therefore, the software needs to solve the high requirements of accuracy in order processing / sales contracts, and continuity in the delivery process.

- At the office, sales staff can control and monitor production flow (through production statistics processes), available inventory (products that can be sold). However, in addition to the automatic functions of the system, in the operation process, enterprises must fix data completion timelines between the locations of use.

- Accordingly, production work often takes place continuously and it is necessary to set a time to close the production data of each day so that the business departments can inherit and capture the actual output of that day => do basis for building orders, making export orders. (For example, it is stipulated that before 8:00 a.m. daily, the production departments at the factory must update and complete the production data of the previous day in order for the business to perform the sales stages).

- From the moment the business completes the order/contract and makes the “delivery orders”, the data will have to be displayed immediately at the Warehouse, the weighing house and the factory accountant to set up the delivery procedures for the customer. Therefore, in addition to the supporting technology of software and hardware, enterprises also need to equip information technology infrastructure systems (servers, internet lines, power systems) to ensure the continuity of the network. Process of production and sale.

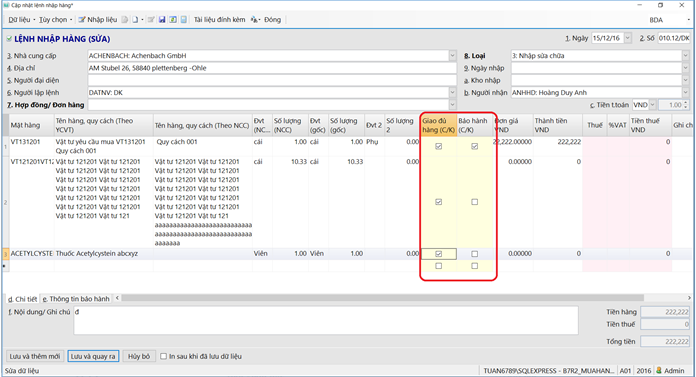

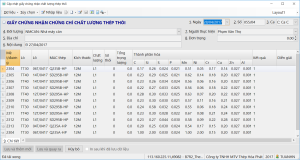

Some images on BRAVO software

Make export order

Make a hold order

Make sales invoice

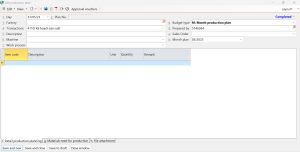

Update production plan

Make a purchase order

- Procurement is under the authority and responsibility of the Purchasing Department (or Materials Department). However, the operating process is related to all parts and departments in the enterprise. Therefore, the application of software to Purchasing Management also needs to separate the application scope in each department and department.

- Handling purchase request/request: at each point of using the software (office, factory, branch), all departments will make “requests/requests to purchase materials” via hard copy (according to the form). prescribed form of the enterprise) => purpose to reduce redundant data types and minimize the number of users interacting on the software.

- After being confirmed and approved by the department head (or person in charge), it will be transferred to a main department (eg Electromechanical Engineering Department, Organization Department) to synthesize all kinds of purchase proposals/requests. supplies and updates to the software. This department will base on the elements of materials (immediate availability, availability, reserves, …) to approve the purchase offers => approved and accepted offers will be displayed on data screen at the Materials (Purchase) Department at Head Office/representative office.

- At the Purchasing Department, the purchasing officer inspects and approves the proposals/requests to purchase materials and conducts the processes of inquiry/collection of quotations/comparison of quotes to submit to the company’s management. approve. After the leader approves, the Purchasing Department proceeds to make orders/contracts (according to the selected supplier, quotation) to purchase.

- Before the goods arrive at the delivery point, the Procurement department makes “import notices” to the relevant departments to prepare for the people and the geographical space for the warehousing process. When the NCC delivers the goods to the warehouse, the staff of the Technical Department will work with the Quality Control Department to inspect the goods. If the standard is met, then sign the “Receipt of goods delivery” signed by the delivery unit, the factory security, the Technical/Quality Department and the warehouse keeper, then enter the warehouse. If they do not meet the standards, they will not be allowed to enter the warehouse and return the goods to the NCC.

- On the system, in addition to the departments directly related to the purchase/import of goods, the requesting departments will monitor the progress and status of goods in order to make “supply/receipt of materials” to warehouse department to export materials.

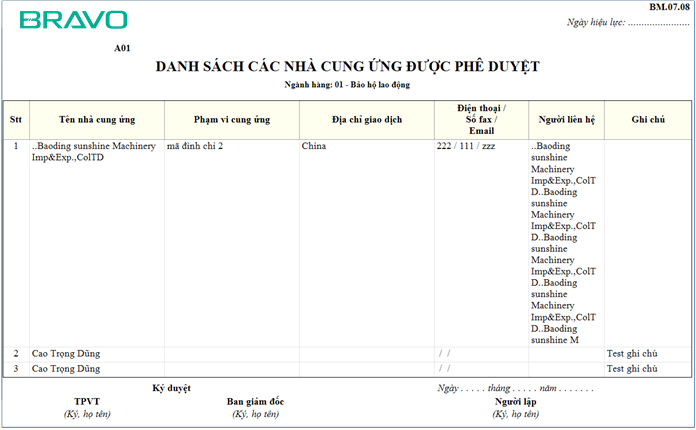

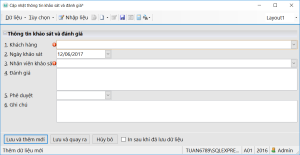

Some images on BRAVO software

Updated proposal to buy supplies

Update supplier quotes

Vendor approval

Make purchase order/contract

Make order to import goods

Make surveys, evaluate suppliers – after purchase

Production characteristics

- Rolled steel products (steel plate, corrugated iron) are the input materials of steel pipe factories. Therefore, tracking of source materials plays an important role in controlling input materials and tracing the origin and quality of finished products and output semi-finished products.

- At each warehouse import and export operation, statistics sheet, … the software builds input information flows, supports users to update groups of units, characteristics of raw materials/semi-finished products/finished products in the process. production process such as: Original winding code / coil code (semi-finished product) / Mac steel / Strip / Production batch, ..

- Through the Production Statistics function, the software can handle the following operations:

- Statistics on the number of products completed by each stage, each working shift, and each production machine (line).

- Statistics of machine stopping time, mold change, tool change, rolling shaft change … according to each shift, machine (line) of production.

- Consumption statistics: Main materials, auxiliary materials, tools, oil, grease, chemicals, electricity.

- Statistics on available inventory levels of each group of finished products (groups of salable items, supporting sales department to be proactive and control inventory)

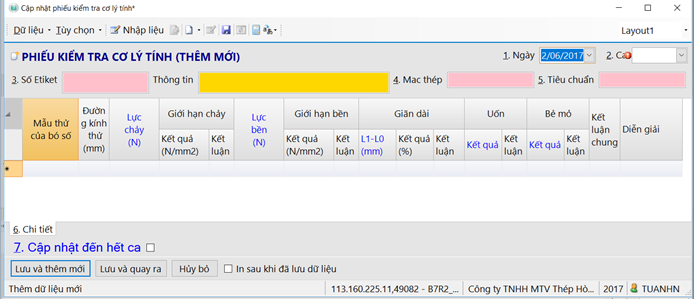

Some pictures on the software

Order and production statistics

Management of machinery and equipment

- Asset and equipment management is especially important for steel pipe manufacturing enterprises, well-managed equipment will help businesses reduce a lot of risks of damage, exploit and operate equipment effectively. thereby reducing the production cost of the enterprise.

- BRAVO solution applied in the management of machinery and equipment at Steel Pipe units:

Manage records of machinery and equipment:

- Update and manage records such as registration, registration, inspection, insurance, details of components, spare parts, etc. of each asset and equipment.

- Attach documents such as certificates, inspection, user/operating manuals, documents, manufacturer’s maintenance regulations, maintenance, … or equipment pictures, equipment file files .

- Update information on handover, allocation and liquidation to the department or personnel directly managing machinery and equipment. Update and manage logs, log usage and operation of each device.

Manage maintenance and repair of machinery and equipment:

- Flexible declaration of types of norms, maintenance and replacement cycles for each device such as the number of days (month, year), number of hours of operation, number of operating kilometers, etc. The declared parameter values are also declared. change over time to match the age of each device.

- Function, report warning items, components, spare parts of each equipment to the period of maintenance and replacement.

- Declare the norm of consumables when performing maintenance and replacement according to the item of each equipment.

- Updating requisitions for purchase of supplies and repairs.

- Alerts the amount of supplies to be purchased to carry out the periodic maintenance plan.

- Updating inspection records of equipment breakdowns, equipment breakdowns, maintenance requests. Plan, monitor, and control internal or external equipment maintenance, repair or fabrication. Monitor equipment maintenance and repair logs.

Interface of Machine and Equipment Management Subsystem

Maintenance request form update screen

The screen updates the plan to repair machinery and equipment

Product Quality Management

- Steel market with high competition among domestic companies and especially competition from Chinese steel products (the country with the number one volume of steel in the world), from a management perspective, Management, supervision and monitoring of output product quality plays a key role in determining the competitive advantage of each enterprise.

- Accordingly, from production to distribution to the market, enterprises need to control and monitor the status of their products. Specifically:

- During production: with input materials (cold rolled products, coils), details must be monitored for each type of material (original roll code, semi-finished roll code) so that quality can be controlled. of each raw material put into production. However, at rolling mills, the output products have been analyzed for the indicators of Mechanical – Physical – Chemical properties and synthesized on the steel grades attached to the surface of each product.

- After production is completed, the software allows updating product indicators/characteristics and printing “quality certificates” for each production batch. When there is a quality problem with feedback from the market, businesses can rely on “quality certificates” to trace the production process of that product: from which roll? Which production batch? Production from any date to any date on the system.

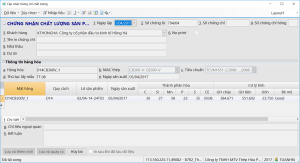

Some pictures on the software

Check incoming goods

Update product quality information

Make and print quality certificates

Effective software application

1. For the Sales department

- The sales department always has accurate and immediate information on production progress, available inventory => optimal support for the transaction and sales negotiation process.

- Continuously update and control information about the delivery process (cars in and out when receiving goods) and track the transport of vehicles for each route as well as output.

- The homogenization of product names and specifications throughout the system ensures the accuracy of transactions in selling, exporting and importing goods throughout the system (minimizing confusion when transactions involve language elements). regional language)

2. Production Dispatching Department

- Always know the statistics on factors related to the production process quickly and accurately, maximum support for the process of moderation and production monitoring.

- By managing the origin and quality of raw materials, and especially capturing the non-production time (machine failure, repair, etc.) as well as the percentage of defective products at each machine, quality can be managed. quantity of each product and trace the origin when detecting defective products.

3. Purchasing department

- Minimizing internal transactions related to the process of purchasing and supplying materials

- Minimize errors related to technical factors, quality and origin of purchased materials.

- Helps to best control supplier quality during purchasing and importing.

4. Parts warehouse

- Be proactive in managing and operating warehouses related to materials and finished products

- Good response for the management and performance evaluation of the warehouse department.

5. Electromechanical engineering department

- Support to manage the system of machinery, equipment and means of transport of factories and enterprises.

- Support management from machinery and equipment information to maintenance and repair plans; updating and looking up the equipment’s operation log helps to improve the productivity and efficiency of the enterprise’s exploitation and operation of machinery and equipment.

6. Accounting department

- Minimizing re-entry of data arising in departments and improving the control role of accountants

- Maximum support for professional tasks that require high accuracy such as cost calculation, product cost calculation

- Maximum support in analyzing and synthesizing production and business results of the whole system.

7. Board of Directors

- Provide the Board of Directors with the most complete, accurate and timely information on all issues related to the company’s production and business.

- Prepare comparative and evaluation reports based on criteria suitable to the characteristics of the business.